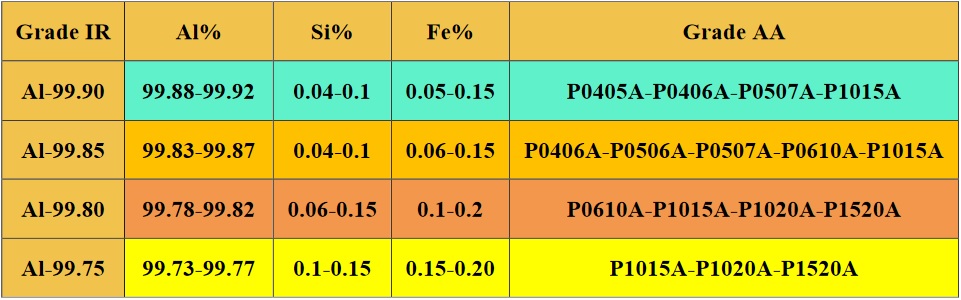

Specifications of production ingots (1000 and 50 pounds)

What is aluminum ingot?

Aluminum ingots is non-ferrous product that is produced by pouring molten aluminum into special molds. These molds come in a variety of sizes and shapes, and the ingots created by this variety have different types in appearance. Today, aluminum is the second most widely used metal in the world after iron. The widespread use of this metal in various industries has led to special attention to its identification and extraction from existing mines in the country.

Applications of aluminum ingots:

- Re-melting industries

- Transportation industries (aircraft, automobile, truck, shipbuilding, railway, etc.)

- Packaging Industry

- Production of cans and foils

- Manufacture of building doors and windows

- Production of building wall coverings

- home appliances

- Electrical transmission lines

- Glass industry

- Manufacture of casting parts

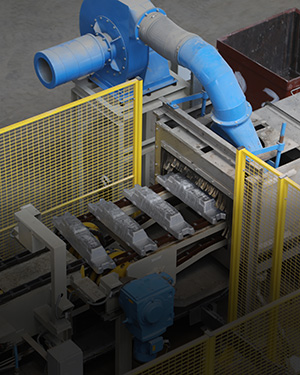

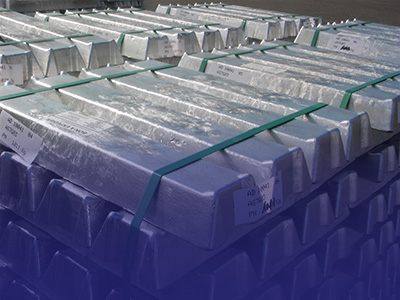

Production capacity of aluminum ingot in the South Aluminum Industries Complex Company

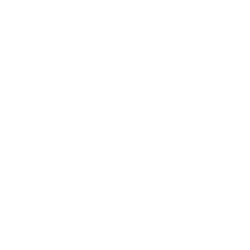

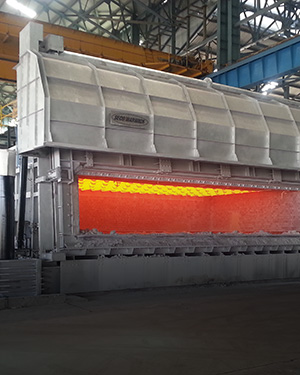

In the foundry workshop No. 1 of the South Aluminum Industries Complex, 144,000 tons of aluminum ingots are produced annually. This volume of the production of aluminum ingots with high purity and excellent quality. The purity of the ingots produced by this factory is about 99.7 to 99.9%.

These ingots are often made of pure aluminum or alloy. According to the forecasts of the executive agents of this company, the net production of this factory can be upgraded to 303 thousand tons per year. This means that a huge amount of domestic needs will be met by these products.

Aluminum ingots

Aluminum

Advantages of using aluminum

1

Flexibility

2

Strength

3

low weight

4

Brilliance

5

Resistance to corrosion and cracking

Types of aluminum ingots

There are different types of aluminum ingots, the percentage of purity and size of which determines their type. These two basic parameters cause the allocation of ingots to different industries and applications. Types of weight of aluminum ingots and their applications include the following:

50 pounds ingots (foundry and machine building industries)